Our Services

SCREEN PRINTING

Screen printing is the best printing method for most apparel products. From classic plastisol to specialty inks and additives, our staff can achieve stellar results for our customers. Screen printing does have its minimums due to the labor that goes into the set-up and preparation per job. However, screen printing is still the most cost-effective printing method. If you can’t meet the minimums, don’t worry, we also offer Direct-to-Garment Printing (DTG) with no minimums and no set up costs.

Plastisol Screen Printing

Plastisol Screen Printing is the oldest and most popular form of screen printing due to its durability and lower cost. Unlike water-based inks, plastisol adheres to the surface material of a garment and when cured does not breathe well and has a heaver feel on the material. This method is not recommended for large and heavy print designs.

Metallic ink: These inks are used to give the print a metal appearance. They are often shiny and brilliant when first printed. Gold, silver and copper are the most common.

Glitter ink: These fun inks are made with a metal flake called crystalina. This is a small flake of reflective foil or plastic suspended in a plastisol base. The base may be clear or tinted. Common colors include gold, silver, red, blue and other various colors.

Glow-in-the-dark ink: The photoluminescent effect is achieved by using a non-radioactive, nontoxic zinc sulfide pigment that absorbs daylight or artificial light. This glowing ink creates a glowing effect in the dark when charged by light.

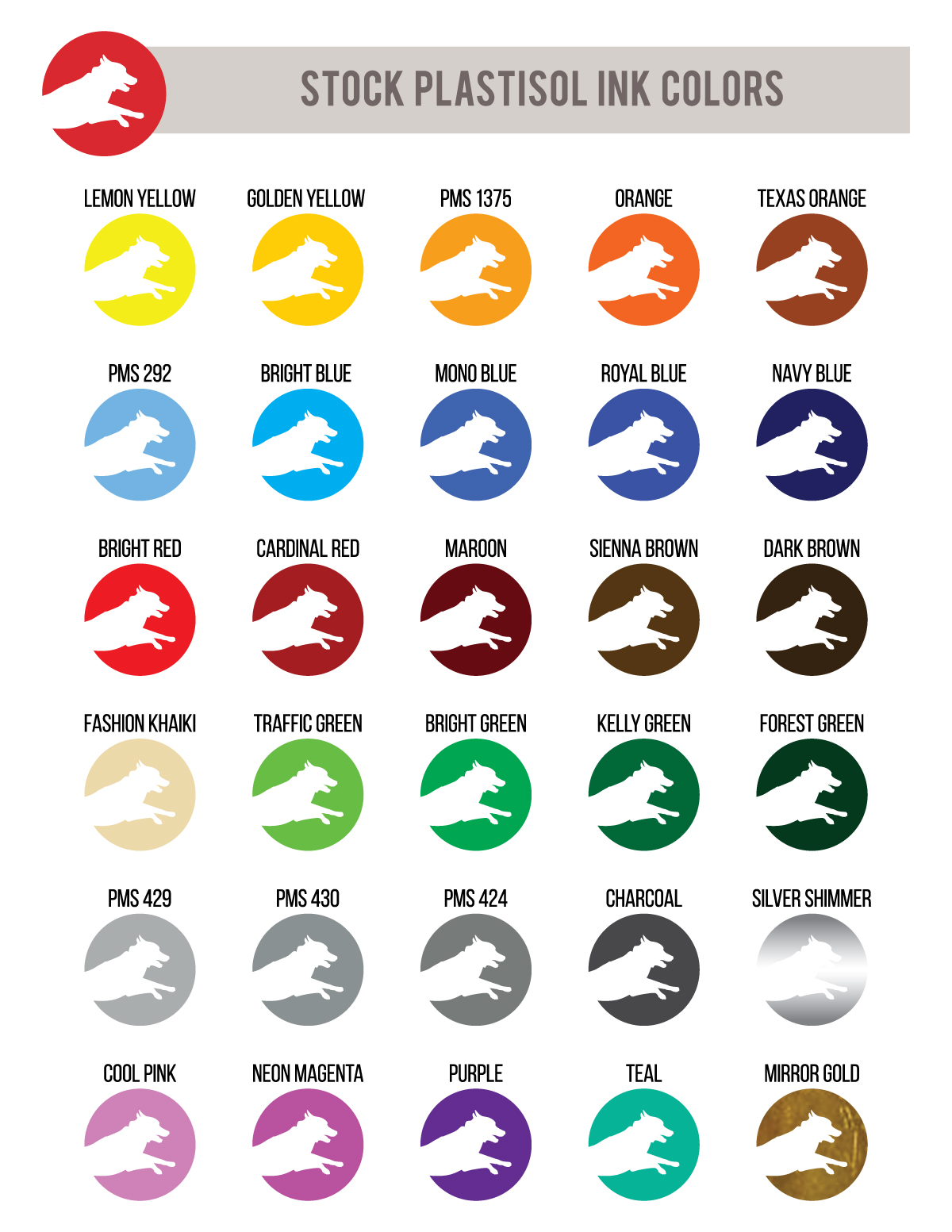

Below are our Stock Plastisol Ink Colors. But you are not limited to these colors. We will Pantone match any color for free!

Water-Based (and Discharge) Ink Printing

Water-Based Ink Printing are known for their velvet-soft prints. These prints are typically found in the high-end fashion retail industry. Water-based inks are screen-printing inks that are water soluble. They differ from traditional plastisol inks in several ways. Water-based inks are much thinner and when printed with, will be absorbed into the fibers of the garment, becoming “one” with the shirt.

Water-based screen printing ink technology has evolved to allow for professional-grade inks to print effectively on both light and dark shirts. Printing water-based ink on dark shirts is substantially trickier and requires an ink additive known as discharge. When mixed with the water-based ink, discharge will remove the garment’s dye color and fully replace it with the ink it has been mixed into. This allows for a softer feel after first washing, even softer than water-based ink normally affords. It is not recommended that discharge ink be printed on any garment that is less than 100% cotton. Although possible, it will not perform as intended and results can be rather unpredictable.

EMBROIDERY

Embroidery is the art of decorating fabric or other materials using a computerized embroidery machine and digitized art files. The process begins with the digitization of the logo or design. When the digitized logo meets your approval, we produce the design on your chosen product.

From the very beginning of the product development cycle, our apparel is designed with decoration in mind. We understand that your brand is your business, so we work to ensure that our decoration methods – which are specifically created for our apparel – create an authentic branding experience. Our goal is to produce a finished piece that looks as though it was custom made just for you.

Standard Embroidery

Standard embroidery is the most common method embroidery. Often referred to as flat embroidery, this process is perfect for most custom embroidered apparel, caps & bags.

Puff Embroidery

3D puff embroidery uses an underlying foam material, which raises a design up allowing for the three dimensional feel and appearance. Your design will really stand out - literally! By using foam embroidery of varying color and widths, it allows us to sew with varying stitch colors and materials. We also double the 3D thread count to ensure the 3D foam embroidery is not exposed under the puff stitching. Choose from tons of different garment types - 3d embroidery hats, bags, and more for an amazing high-quality embroidery look!

HXD

The New Dimension

Introducing HXD, a unique decoration method that offers all new possibilities for your branded apparel. Creating a subtle pop from the apparel surface, HXD brings a whole new dimension to your logo.

The New Quality

HXD uses a patented manufacturing process to combine the best attributes of two methods: the surface interest and high perceived value of embroidery, and the unlimited color, incredible detail and location versatility of True Edge™ Transfer.

The New Elegance

HXD adds both a reflective quality and new dimension to subtle tone-on-tone decoration.

Click here to learn more!

Tackle-Twill & Appliqué

Tackle Twill, or applique, involves sewing down a number or letter made by cutting pieces of one material and applying them to the surface of another material usually with a nylon twill. Basically, tackle twill begins with a "patch" of sorts that is applied to the jersey, shirt, hat or other garment that is then sewn to the material for a more rugged finish.

DIRECT-TO-GARMENT (DTG)

With DTG printing, a printer directly applies the ink onto the t-shirt with inkjet technology. It’s literally like an ink-jet printer, but for t-shirts instead of paper. A special printer prints the ink directly onto the garment in the desired design. DTG uses specialty water-based inks, which are absorbed by the fibers of the garment. Direct-to-Garment is best achieved with high-cotton content apparel as the ink does not adhere well to polyester.

The advantages of direct-to-garment printing are:

- Practically any image can be printed, including highly detailed designs like photographs.

- No set-up charges.

- No minimum order.

DYE-SUBLIMATION

Dye-Sublimation printing is the most detailed way to customize apparel, with the ink becoming part of the fabric, it leaves a very soft-hand touch to the garment. Sublimation printing is also very durable; images won’t crack, peel or fade. Color remains vibrant even with extensive washing.

Images are produced using a 4-color process, allowing unlimited colors and photographic-like images. Our presses are capable of everything from spot color to all-over printing of a garment.

HEAT TRANSFER

Heat transfer printing is the process of applying heat-applied materials to various items with a heat press. Heat-applied materials contain a heat-sensitive adhesive on one side; when heat is applied by a heat press to the material, the material adheres to the material to which it is being applied.

- Rhinestones/Studs

- Glitters

- Faux Sequins

- Sublimated Satin

- Flocking

- Mixed Media Transfers

Let us make your one-of-a-kind garment shine!!!

We offer a wide array of Heat Transfers: Hotflix Glitter, Foil, Lace, Sequins, Embroidered Applique Patches, Flocking, 3-D Transfers, Glow-in-the-Dark, Sublimated Foil, Plastisol and Glitter Litho, Rhinestones, Rhinestuds and Nailheads and many more!

FINISHING

The Finishing Touches

Once your garment is complete: put your name on it! Add a label to your garment letting everyone know your brand. We offer a variety of ways to label your garment.

- Tagless Printed Labels

- Hang Tags

- Woven Labels

- Embroidered Patches

If your brand requires special packaging, we’ve got you covered there too. We can size label and individual polybag each garment for protection and for a great presentation.